The holes should be located every three inches along the T-track. Mark the holes for the mounting screws into the T-track. After the glue is dry use a hand saw to trim the overhanging points off the fence supports. The outer supports are placed 1-1/2” from the ends of the fence and the inner supports are 8-1/2” from the edge. Next, glue and clamp the upper fence to the lower fence.Ĭut 2-1/2”x 2-1/2” triangular fence supports from the left over ½” plywood. Trim the upper fence to size and then plough a dado for the T-track. radius semicircle makes it easy to remove the fence portion of the drill press fixture while it remains mounted to the drill press platen. It’s best to cut the pieces oversize slightly and then trim them to size once the glue has dried.Ĭut the lower fence base to size and then cut the semicircle in the rear. Mate the surfaces for the fence just as you did for the tabletop so any warps oppose each other.Ĭlamp the fence halves to the top of your table saw in order to keep them perfectly flat. Make this cut from both ends, following the lay out in Figure B. Move the workpiece through slowly and steadily and let the dado blade do the work. You don’t want the T-track to be above the tabletop at any point.Īfter cutting the glue up to final size (Figure B), set the fence 5-3/4” from the fence and plough your dado. It’s better if the depth is a hair deeper than too shallow. With your table saw unplugged set your dado blade to the height of the T-track. Too late and it’ll be too hard to remove. Check the glue frequently for it to be the right consistency for scraping. Scrape the glue from cutout before it gets hard. Use at least 60-pounds of weight, and let it sit for at least three hours. You can see I stacked it pretty high to get enough weight onto the cauls. Don’t forget to put a later of wax paper or something similar between the plywood and your saw surface so glue squeeze out doesn’t get all over the saw table. Place straight cauls onto the upper and lower plywood layers so pressure can be placed evenly across the entire surface.

The pins will keep the plywood panels from drifting while you pile on weights. pinner after positioning the panels on your table saw top. I used an old membership card cut with a pinking shears to help spread the glue evenly. Spread glue over the lower plywood layer of the drill press table.

DREMEL DRILL PRESS JIG HOW TO

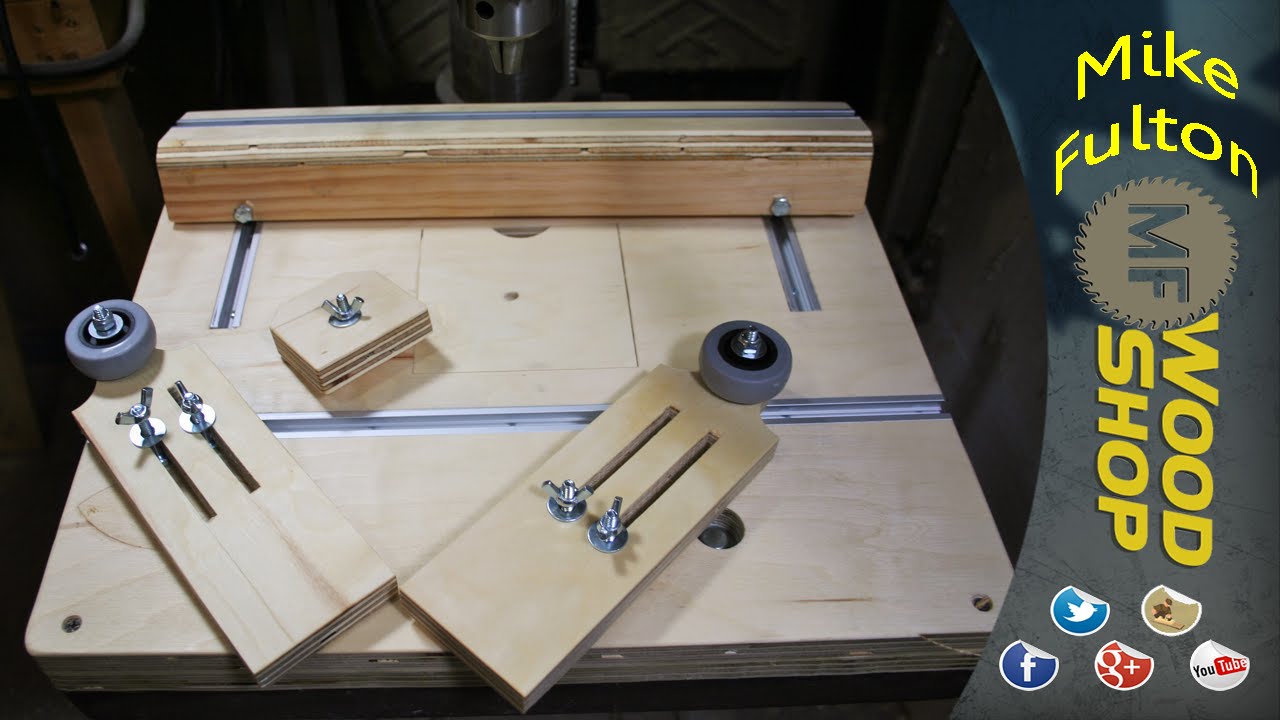

If the plywood has a slight warp, check out the text below for how to deal with it.Ĭreate a finger hole for the replaceable drilling squareĭrill a 1” hole 3/8” deep into the upper base layer to provide a finger hole to help remove the drilling square.Ĭut through the upper plywood layer with a fine-toothed jig saw along your guidelines for the replaceable 4” x 4” plywood insert. It’s nothing to get too precise about, a 1/4” difference one way or the other will still be fine. Check your drill press for the dimensions from the column of the drill press to the center of the chuck. Mark the center and then mark the cutout for the replaceable drilling square. This will enable you to trim the piece to final dimensions after gluing. Start by cutting two pieces of 1/2″ Baltic birch plywood at least 1/2″ larger than the finished dimension of the table as shown. Layout the drill press table with your framing square The base and fence are made from two layers of Baltic Birch plywood for rigidity. Follow the step-by-step drill press table plans for details to build your own.įigure A – Here is the construction of the drill press table. The most expensive items are the T-track and the hold-downs. Best yet, this jig is a project you can work on in your spare time over a couple days and complete for less than $50.

The hold-downs are great for holding items still for delicate or precise hole drilling. The cast round table below the chuck isn’t woodworker friendly or even metalworking friendly. Once you build this fixture you’ll love its adjustable fence for drilling equally centered holes and the stop block that lets you make repeatable drilling operations in conjunction with the fence. Stationary drill presses are definitely not set up for DIY woodworking. This is a shop fixture that’s worth getting started on immediately.

0 kommentar(er)

0 kommentar(er)